Clinical trial to test engineered skin for severe burns starts in Melbourne’s Alfred Hospital

Clad head to toe in a hair net, mask, gown, gloves and shoe-coverings, Shiva Akbarzadeh gestures to the laboratory around her.

“This is where the magic happens,” she says.

On this particular day, there is no magic happening. The equipment’s switched off; pipettes, flasks and other lab gear is stowed away.

But when things ramp up, they really ramp up.

That’s because this room, at the Alfred Hospital in Melbourne, is where Monash University’s Dr Akbarzadeh and her research team make squares of engineered human skin.

The two incubators in Shiva Akbarzadeh’s skin engineering lab run constantly when she and her team are making grafts for a patient. (ABC Science: Belinda Smith)

Machines currently sitting silent on the lab benches will work non-stop for weeks on end. Researchers will tend to live cells bathed in nutrient-rich broths under the whirring drone of what’s essentially an industrial range hood.

This team is running a clinical trial to test the safety and efficacy of their engineered skin on people with severe burns covering at least 20 per cent of their body.

When trial participants arrive, the researchers will take a small sample of their healthy, unburnt skin and use it to grow billions of new skin cells in the lab’s incubators.

Those cells will then be suspended in sheets made of strong but supple hydrogel, which are surgically grafted onto the patient.

It’s too early to report any long-term results yet, but they’ve so far used their latest iteration of engineered skin on an adult and a child.

“The results have been really positive and encouraging,” Dr Akbarzadeh said.

“Most wounds were closed within two weeks with little sign of early scarring.”

Her lab is one of a handful around the country working to create engineered skin to help deep burns heal quickly while giving patients the best possible quality of life.

And they continue a long history of Australian burns research and technology that’s now used on operating tables the world over.

When traditional grafts are impossible

How well a burn heals depends on a range of things, such as a person’s health, their age (older people don’t heal as quickly as younger people), and the size and depth of their burn:

- Superficial burns — also called first-degree burns — only affect the very outer layer of skin or epidermis

- Partial thickness or second-degree burns also damage the second layer of skin, which is called the dermis

- Full thickness or third-degree burns are the most serious. They burn through the epidermis and dermis into the underlying muscle, bone or fat below.

While small or superficial burns usually heal within a few weeks, it’s not the case with large, deep burns. They heal incredibly slowly, if at all. This means people with extensive burns are also at huge risk of infection.

The gold standard treatment for the most serious burns is to take a thin layer of skin from an unaffected part of the body — usually the epidermis and part of the dermis — and surgically graft it on the burn site.

Being the patient’s own skin — known as an “autograft” — it’s less likely to be rejected than skin donated from someone else.

To make it stretch further, the autograft can be perforated or “meshed”.

Surgeon Heather Cleland has been involved in the Alfred Hospital’s burns unit for more than 20 years. (Supplied: Alfred Health)

But even if an autograft helps close a wound, the skin is prone to scarring. This can affect a person’s day-to-day life and restrict their movement — especially if it’s on their face or over joints, Heather Cleland, a reconstructive plastic surgeon at the Alfred Hospital, says.

“In the process of trying to treat burns and get these patients healed, we routinely take skin grafts from areas that have not been burned, so we create a second injury, if you like, and extend the damage to the person’s skin.”

For older people, who don’t heal as well as younger folk, this can be a serious problem.

And if someone has burns to most of their body, an autograft may not be possible at all.

So researchers are working on ways to reduce or eliminate the need for autografts by making many skin cells from very few.

Recipe for lab-grown skin

Perhaps the best-known cell therapy for burns is ReCell, a technology developed by Australian surgeon and burns specialist Fiona Wood and her collaborator Marie Stoner more than 30 years ago that produces “spray-on skin”.

It works like this: A small piece of skin, taken from a patient on the operating table, is placed in an enzyme cocktail that breaks the skin into its cells, a bit like how a brick wall can be deconstructed into individual bricks.

The cell-rich liquid is then sprayed onto the entire cleaned wound, where the cells start rebuilding dermal and epidermal skin layers and accelerate the healing process.

Spray-on skin can be used alongside traditional skin autografts, and alone on partial-thickness burns. But for people with large, full-thickness burns and for whom harvesting autografts is not an option, surgeons need something a little more heavy-duty.

This is where engineered skin sheets show promise.

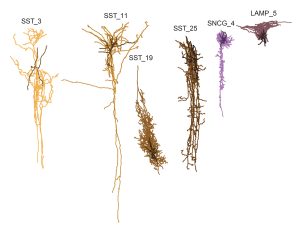

Engineered skin sheets produced in the Alfred’s lab are around 12 centimetres across, and the scientists can prepare at least nine in four weeks. (Supplied: Shiva Akbarzadeh)

Skin engineering labs around the world use roughly the same technique to make their “skin”: take a small sample of healthy skin from a patient, encourage the cells in the sample to make more of themselves, then suspend them in sheets to be grafted.

But while it sounds relatively straightforward, this is not the case.

One issue with engineered skin is vascularisation: getting the body’s blood vessels to quickly grow into the graft and bring nutrients to the cells within.

Dr Akbarzadeh’s hydrogel sheets, in which she embeds a patient’s lab-grown skin cells, are made from donated platelets from the Lifeblood service that have expired: so while they can’t be used for transfusions, they can be used in research.

She says the platelet-rich hydrogel not only holds the skin cells in place, but “has inherent antibacterial properties and also promotes vascularisation”.

Another problem is time. It takes four to six weeks — not to mention plenty of people-power — to make enough skin cells for the manufactured grafts.

While that’s happening, surgeons cover deep burns with a synthetic dressing called “biodegradable temporising matrix” or BTM.

It’s an invention which came out of the CSIRO in the early 2000s, and is now used on surgeon’s tables around the world, says Jo Maitz, a surgeon and leader of the burns and reconstructive surgery research group at Concord Hospital in Sydney.

“It’s been something that has really changed the world of burn surgery.”

NovoSorb BTM is a biodegradable plastic medical scaffold produced by CSIRO spin-off company PolyNovo. (Supplied: PolyNovo)

The BTM acts like the dermis, and buys time for engineered skin to be produced. Grafts can then be placed directly over the BTM dressing, which eventually breaks down.

Bronwyn Dearman, principal medical scientist at the Royal Adelaide Hospital’s skin engineering laboratory, knows BTM’s development well.

She and her colleague John Greenwood conducted studies to refine the material, which was developed in Adelaide.

These days, part of her lab’s research program is “cultured composite skin”.

Ideally, surgeons want large sheets of engineered skin, Dr Dearman says: “If you have small pieces, it may leave a patchwork quilt-like appearance [on the body] and is more time-consuming for application.”

So, as part of her PhD studies, she built a bioreactor capable of producing pieces of cultured composite skin 25 centimetres square.

In 2018, the lab’s cultured composite skin was used on limbs and chest of a 32-year-old man who came to the hospital with burns to 95 per cent of his body.

Years later, the man is living independently.

Dr Dearman and her team are now refining their composite skin process.

“Our ultimate goal is to reduce the use of skin autografts,” she says.

When will engineered skin be widely used?

Being able to quickly and cheaply generate bespoke skin grafts not only has implications for burns, but other types of chronic wound too, such as diabetic foot ulcers.

The burns and reconstructive surgery group at Concord Hospital — which has established a skin biobank to speed up its research — is looking at ways to not only generate cells faster, but also reduce complications that can come with scarring.

In most wounds, long, thin cells in the dermis layer contract to pull the edges of the wound together. Once the overlying epidermis has completely grown across and closed the wound, those contracting cells get a signal from their surrounds and naturally die off.

But in burns, the contracting cells don’t get the message. They keep pulling. And this means many people with burns end up with thick, raised scars, called hypertrophic scars, Dr Maitz says.

To counteract this, Dr Maitz and her colleagues are exploring the use of Botox: “It can reduce the activity of the specific cell that is responsible for hypertrophic scarring.”

Then there are other avenues to improving burn healing, such as cell “rejuvenation”.

Young skin stem cells proliferate quicker than older stem cells, so finding ways to turn back the molecular clock could help get engineered grafts on people who need them faster.

Much of this work, and that of other labs, is still in the early stages.

So while engineered-skin trials are looking promising, there’s still a way to go before such grafts are completely indistinguishable from skin a person typically grows on their body.

“Every skin lab around the world is working on the Holy Grail — producing skin that is functionally and physiologically viable, and has pigmentation, hair follicles and sweat glands,” Dr Dearman says.