Treatment of tooth wear with zirconia crowns

Zirkonzahn presents a case of tooth wear which was remedied with monolithic single crowns made of Prettau 3 Dispersive zirconia.

The patient, suffering from abraded teeth caused by para-functional habit, requested a complete rehabilitation to restore her smile. The planned restoration consisted of 28 monolithic single crowns milled with Prettau 3 Dispersive zirconia (Zirkonzahn).

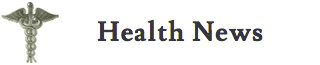

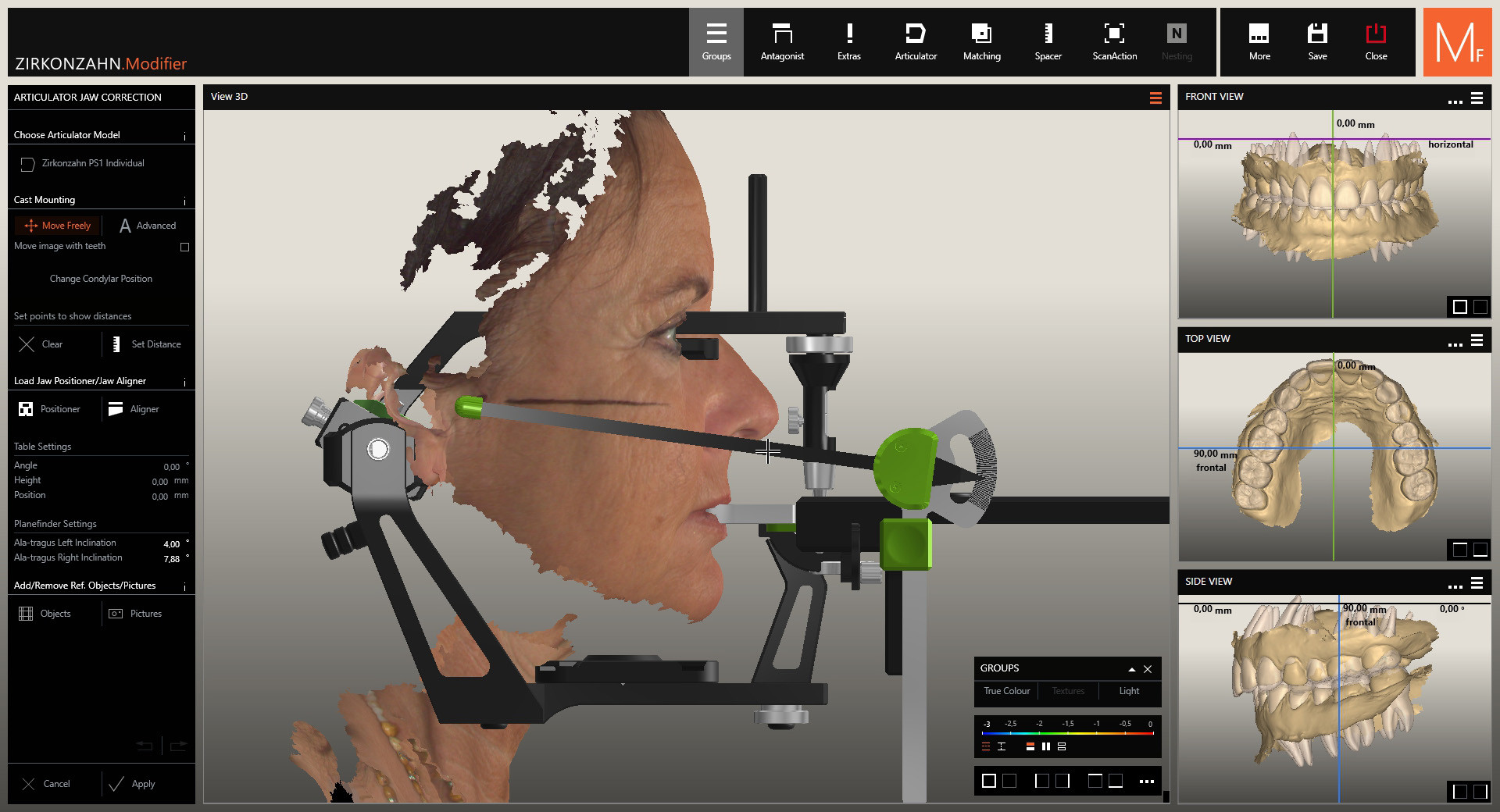

After accurate digital patient data acquisition by the dentist, the dental technician could design two mock-ups (lower and upper jaw), which were used to check functional, phonetic and aesthetic aspects in the patient’s mouth. Subsequently, the dentists proceeded with a minimally invasive preparation of the tooth structure. This was followed by an additional intraoral scanning of the clinical situation.

Further control steps were then carried out. First, 28 crowns were designed and milled out of the radiopaque Exmon Basic X-Ray resin to check the restoration fit in the patient’s mouth by means of X-rays. Afterwards, temporaries were manufactured, which were worn by the patient until insertion of the final zirconia restoration.

Production of crowns

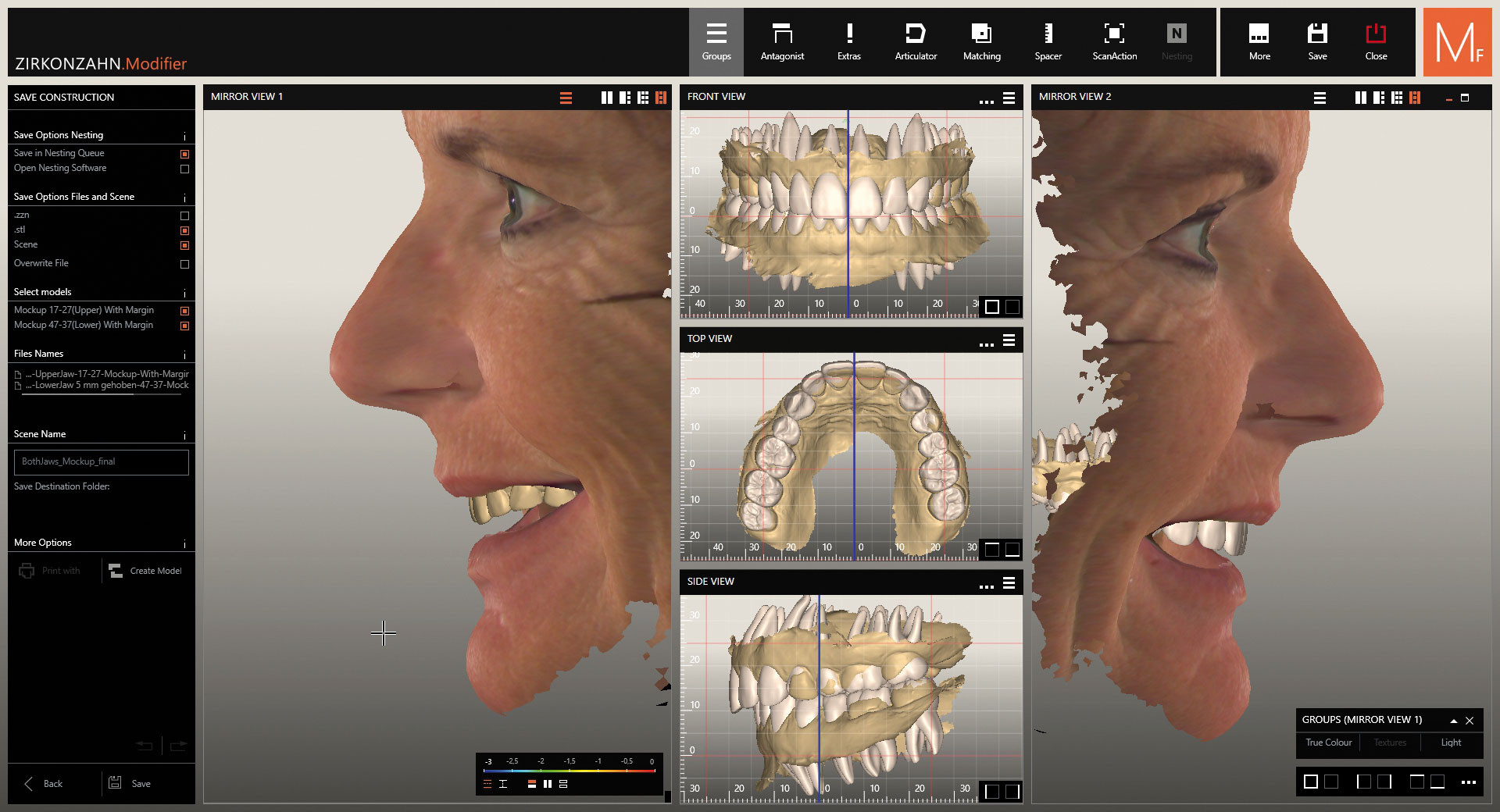

The dental technician designed the 28 final single crowns in the Zirkonzahn.Modellier software. The design was based on the tooth set-up carried out previously in Zirkonzahn.Modifier. The crowns were milled out of a Prettau 3 Dispersive zirconia blank. This is already provided during the manufacturing process with a triple gradient of translucency, flexural strength and natural colour. The crowns were produced using the new M6 Teleskoper Blank Changer milling unit and sintered in the Zirkonofen Turbo, using the speed-sintering program for zirconia.

The Zirkonofen Turbo furnace, developed and produced in-house by Zirkonzahn (South Tyrol) is particularly advantageous. It permits the sintering of smaller zirconia structures starting from 75 minutes. Compared to the standard program, the Ultraspeed program cuts the sintering time by 84% and reduces electric consumption by 81%.

In addition to the pre-installed Zirkonzahn sintering programs, the user can easily and quickly create individual programs directly on the touch display of the furnace. As well as via the mobile Zirkonzahn.App, which can also be used to monitor the Zirkonofen Turbo remotely. The round shape of the sintering chamber ensures optimum heat distribution and a uniform sintering of all zirconia elements. Due to its large volume of 0.9L, up to 120 zirconia elements or up to three full-arch bridges can be sintered simultaneously.

Finishing touches

Once the restoration fit was approved, the single crowns were characterised using the ICE Stains 3D by Enrico Steger, glazed with glazing material, and fired in a single step thanks to the All-In-One Technique. The single crowns were then minimally layered with Fresco Enamel Fluo in the vestibular tooth area and fired once again to lightly individualise the tooth form and achieve a natural-looking surface structure.

The final zirconia crowns were then handed over to the dentist and inserted in the patient’s mouth. A functional and phonetic check confirmed the treatment’s success.

ICE Stains 3D by Enrico Steger are three-dimensional stain colours with special depth effect for surface colouring of full zirconia, ceramics and press ceramic. With the new ICE Stains 3D Blue Lightning shade, it is possible to characterise the incisal area of zirconia restorations. Due to its high level contrast and the resulting colour intensity, this shade can be applied very thinly and precisely. This reproduces a totally natural-looking incisal effect.

Fresco Ceramics, ceramic pastes for veneering gingival and vestibular tooth regions, for monolithic as well as slightly reduced zirconia structures. With Fresco Enamel Fluo, a natural fluorescent effect can be achieved with application of a thin layer of product.

For more information, visit www.zirkonzahn.com.